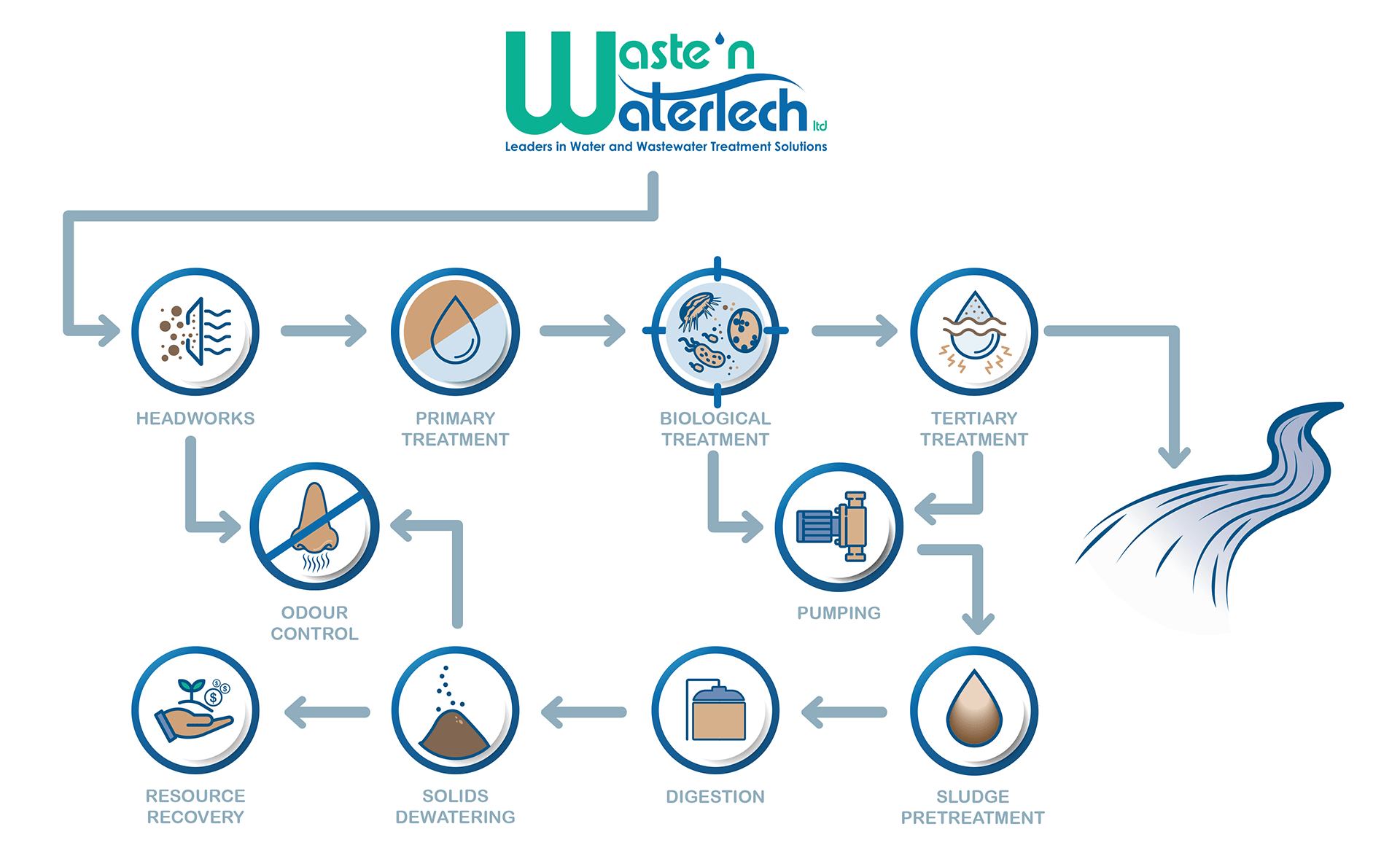

Western Canada’s Leader in Water, Wastewater, and Biosolids Treatment Equipment

Waste’n WaterTech Ltd. is the exclusive representative for over twenty manufacturers from Canada, the United States and Europe, totalling over one hundred product solutions for water, wastewater and biosolids treatment.

Latest News

Our most recent blog posts