Aeration is important for providing sufficient DO for aerobic organisms performing BOD removal and nitrification in activated sludge plants, as well as keeping the biomass in suspension. The nitrification capacity can be varied in relation to DO control in two ways: by adjusting the aeration intensity or by adjusting the aerated volume.

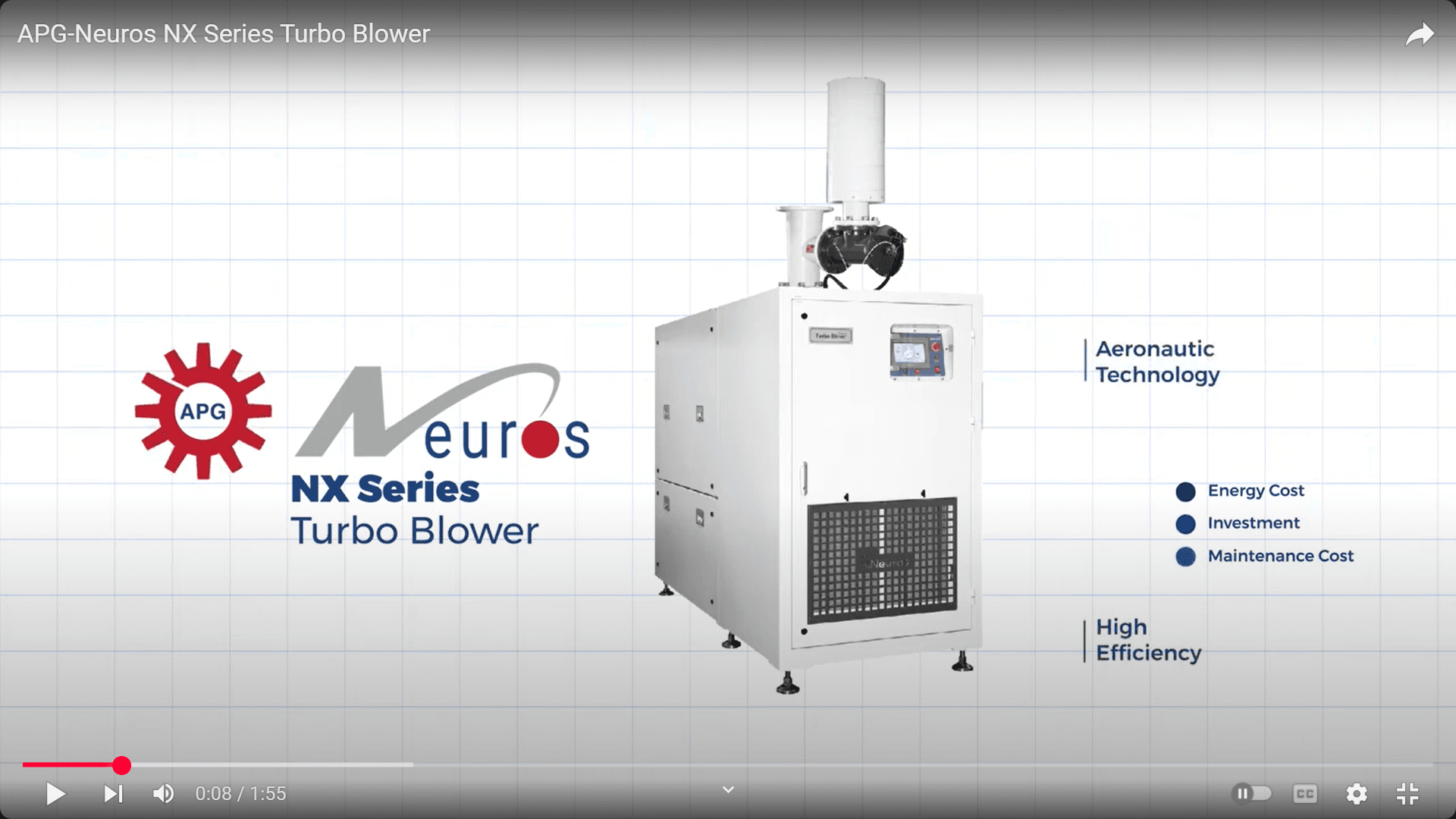

APG-Neuros Turbo Blowers are energy efficient, reliable, high-quality products that are easy to install and require minimal maintenance. They have a smaller footprint and are low in noise and vibration. Crafted using the most advanced aerospace technologies, they provide operational flexibility through easy controls, monitoring and diagnostics. Turbo-blower NX Series available with both Air Bearing and Magnetic Bearing technology, 1MW Series and Gas Turbine Turbo-blowers are available.

Aqua-Aerobic Systems has been designing biological systems since 1969 and has over 1,000 systems installed worldwide. Their suite of biological processes ranges from the tried-and-true Sequencing Batch Reactor (SBR) Technology to the breakthrough AquaNereda® Aerobic Granular Sludge Technology.

This technology is geared towards small-to-medium applications looking to achieve anywhere from rudimentary BOD/TSS removal, all the way to advanced Biological Nutrient Removal (BNR) in a small footprint. Aqua-Aerobic Systems’ SBR is designed as a true batch process, never allowing raw influent to enter the system while treated effluent is being decanted. Their SBR also counts on fully retrievable mixing and aeration equipment, eliminating the need to drain the tanks for equipment repairs.

Aqua-Aerobic Systems is the exclusive provider of the AquaNereda® Aerobic Granular Sludge Technology in North America. This technology, developed in the Netherlands, harnesses the benefits of granular sludge to provide a system that can perform enhanced BNR while using as little as 25% the footprint of conventional activated sludge systems, as well as only consuming 50% of the energy. Aerobic Granules exhibit excellent settling performance and are extremely robust in the presence of fluctuating loading, pH, and toxicity.

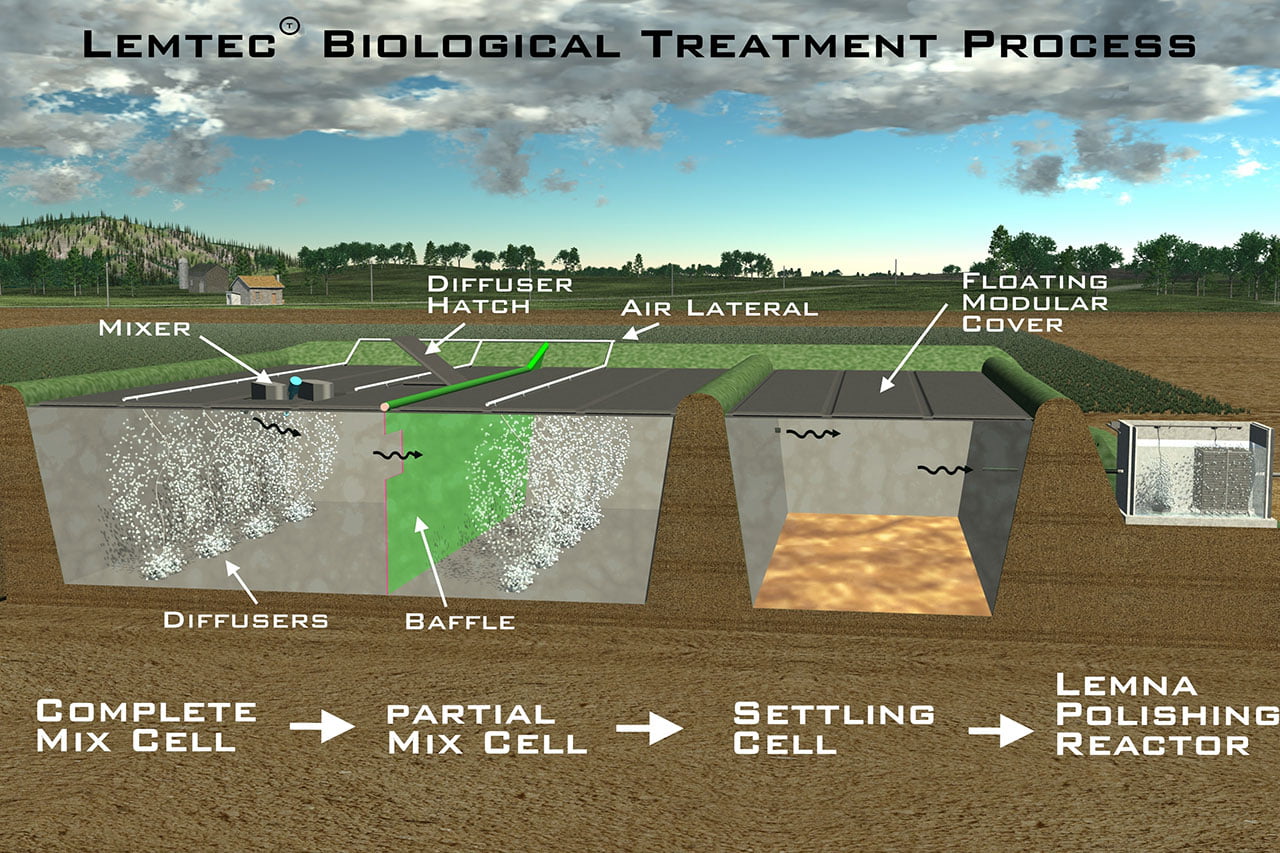

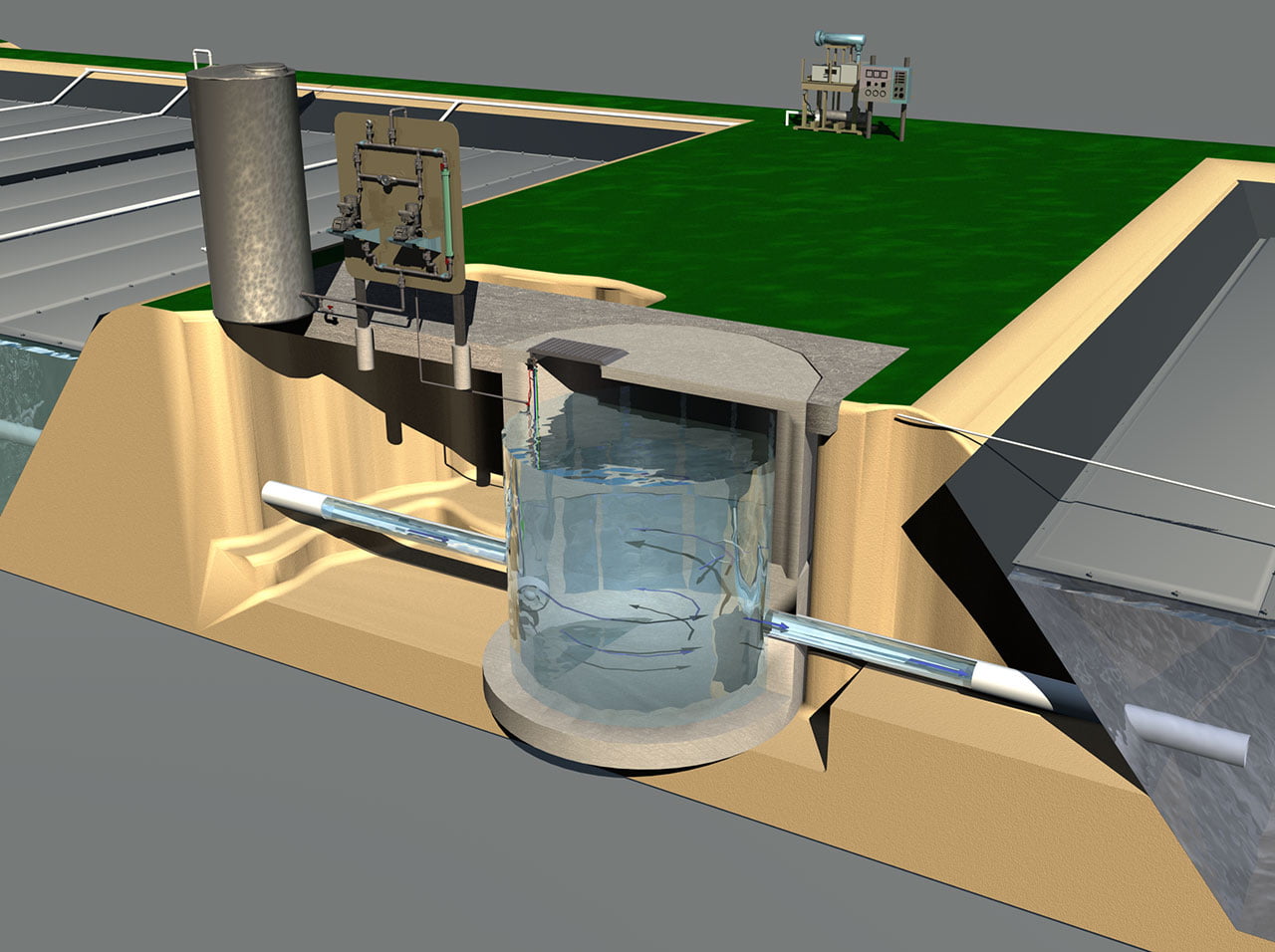

The LemTec Biological Treatment Process™ (LBTP) is an advanced, aerated lagoon treatment process capable of meeting some of the most stringent treatment parameters. This state of the art treatment process focuses on eliminating many of the shortcomings of traditional aerated lagoon processes and enhancing many of their benefits.

LET’s innovative LBTP Process achieves year-round effluent limits as low as 10 mg/L BOD, 10 mg/L TSS and 1 mg/L NH3-N, 1 mg/l Total Phosphorus and 10 mg/l Total Nitrogen at a fraction of the cost of traditional wastewater treatment systems. With a smaller footprint than traditional lagoons and lower capital and operating costs than mechanical treatment processes, the system allows for easy expandability for future needs.

The LET Polishing Reactor™ (LPR) provides effective and affordable supplemental BOD removal and ammonia nitrogen (NH3-N) polishing at municipal and industrial wastewater treatment facilities. The LPR is a submerged, attached-growth media technology that can be included at the end of a custom-designed LET biological wastewater treatment process or added to an existing system as a tertiary treatment for Ammonia removal and BOD polishing.

This proven wastewater treatment technology enables LET to deliver guaranteed results for new and existing plants, as the LPR consistently achieves year-round effluent limits as low as 10 mg/l BOD, 10 mg/l TSS and 1 mg/L NH3-N.

The LemTec™ Phosphorus Removal System employs a chemical dosing system, low horsepower pumps and durable mixers to achieve guaranteed results in the most efficient and cost effective way possible. This well-established and proprietary technology was developed by LET for our municipal and industrial clients as a guaranteed solution able to achieve low phosphorus levels economically and with minimal maintenance required. With the addition of coagulants such as alum or ferric chloride, precipitates are formed that can then be removed along with waste biological sludge to ensure our customers’ effluent wastewater meets regulatory effluent T(P) limits of 1 mg/l.

Membrane Aerated Biofilm Reactor (MABR) is a unique attached growth biofilm (fixed film) aeration system which allows for low energy delivery of oxygen. The biomass grows on the outer surface of the MABR strands and receives it’s oxygen from the air flowing on the inside of the hollow tubes. This form of aeration is much more efficient than conventional diffused aeration, leading up to 75% less energy consumption for the same amount of treatment. Being a fixed film technology, the MABR also benefits from greater resiliency, and up to a 50% reduction in waste biomass production. The drop in Oxymem MABR module can increase the amount of wastewater that can be treated within an existing conventional activated sludge system, thereby extending the life and capacity of a municipality’s existing infrastructure.

The BioDoc™ Trickling Filter Rotary Distributor is a patented system for optimizing the performance of trickling filters. It consists of a motor drive, a programmable logic controller (PLC) and a flexible program of speed variation designed for individual treatment plants. If power to the unit is stopped due to outage or interruption, the motor disengages the gearing, allowing the unit to spin hydraulically until power is restored. With the dosing rate optimized, the trickling filter can become the most efficient process equipment in the plant, and plant performance overall is greatly improved.

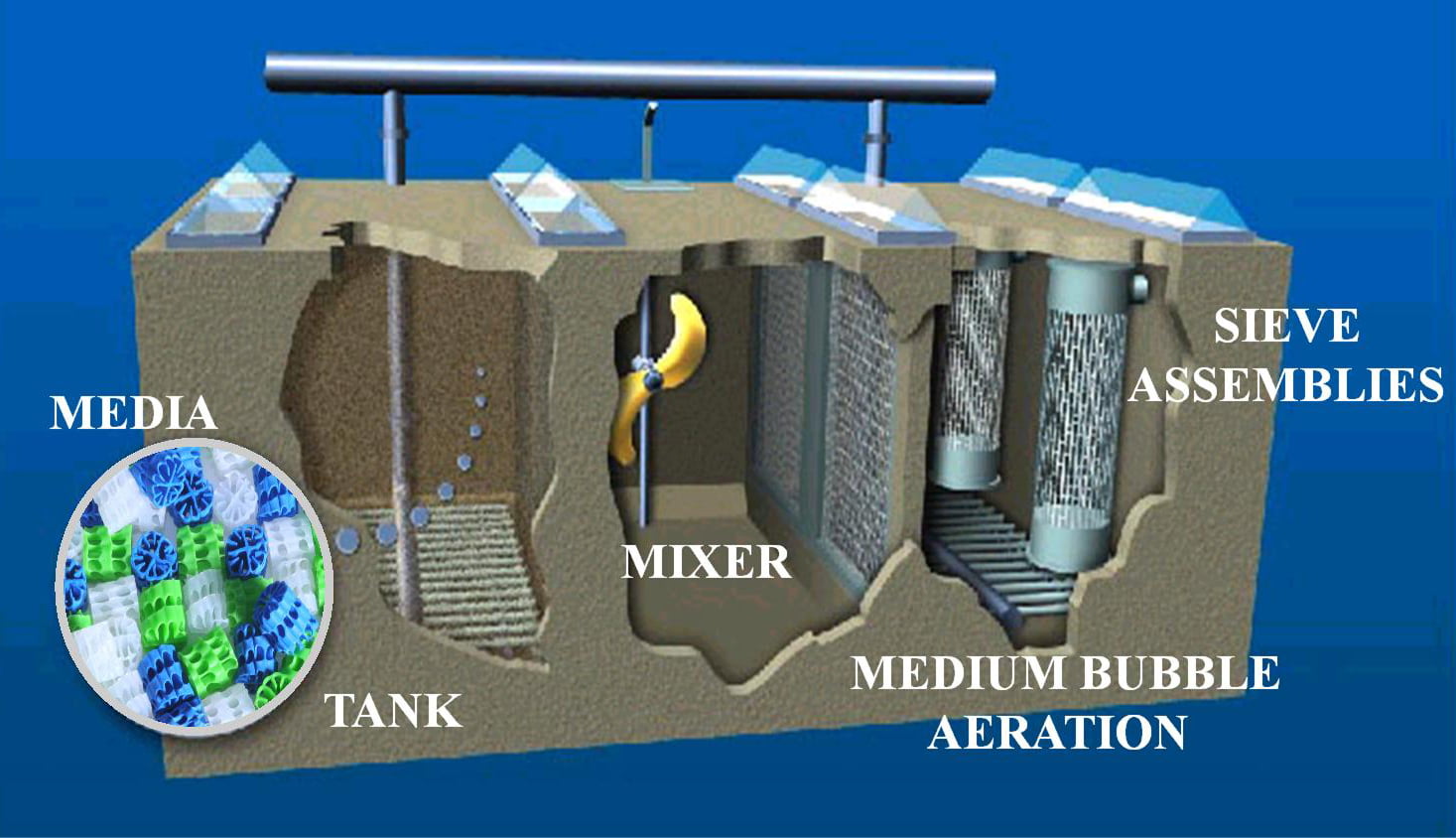

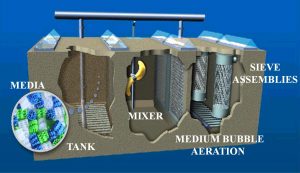

The Moving Bed Biofilm Reactor (MBBR) process is an innovative fixed film (attached growth) biological process. MBBR allows for an extremely small biological system footprint which is robust and easy to maintain. Bacteria grow and thrive on specially designed bio-media with a maximized surface area. These bacteria digest and convert soluble material to biomass which can then be removed downstream using a WWW dissolved air flotation (DAF) unit.

WWW also specializes in the combination of MBBR technology with the Integrated Fixed Film Activated Sludge (IFAS) process for advanced wastewater treatment to meet more stringent nutrient removal limits.

Both MBBR and IFAS are easily retrofitted into existing facilities and can significantly increase the capacity of an existing conventional wastewater system.

World Water Works’ inDENSE system is a gravimetric selection technology that provides a method for retaining the denser biomass while wasting out the lighter fraction of the MLSS in the treatment system. This can lead to improved settling characteristics, increasing process throughput and performance, and has also been shown to promote enhanced biological phosphorus removal.

The inDENSE system utilizes specially designed hydrocylones to select for denser flocs/solids to be recycled while wasting the lighter solids. Designed as a modular system, inDENSE is easily integrated into any existing plant for a low capital cost investment with a rapid rate of return.