BioForceTech is a truly innovative solution for handling of sewage sludge and organic waste, transforming biosolids into valuable energy and biochar.

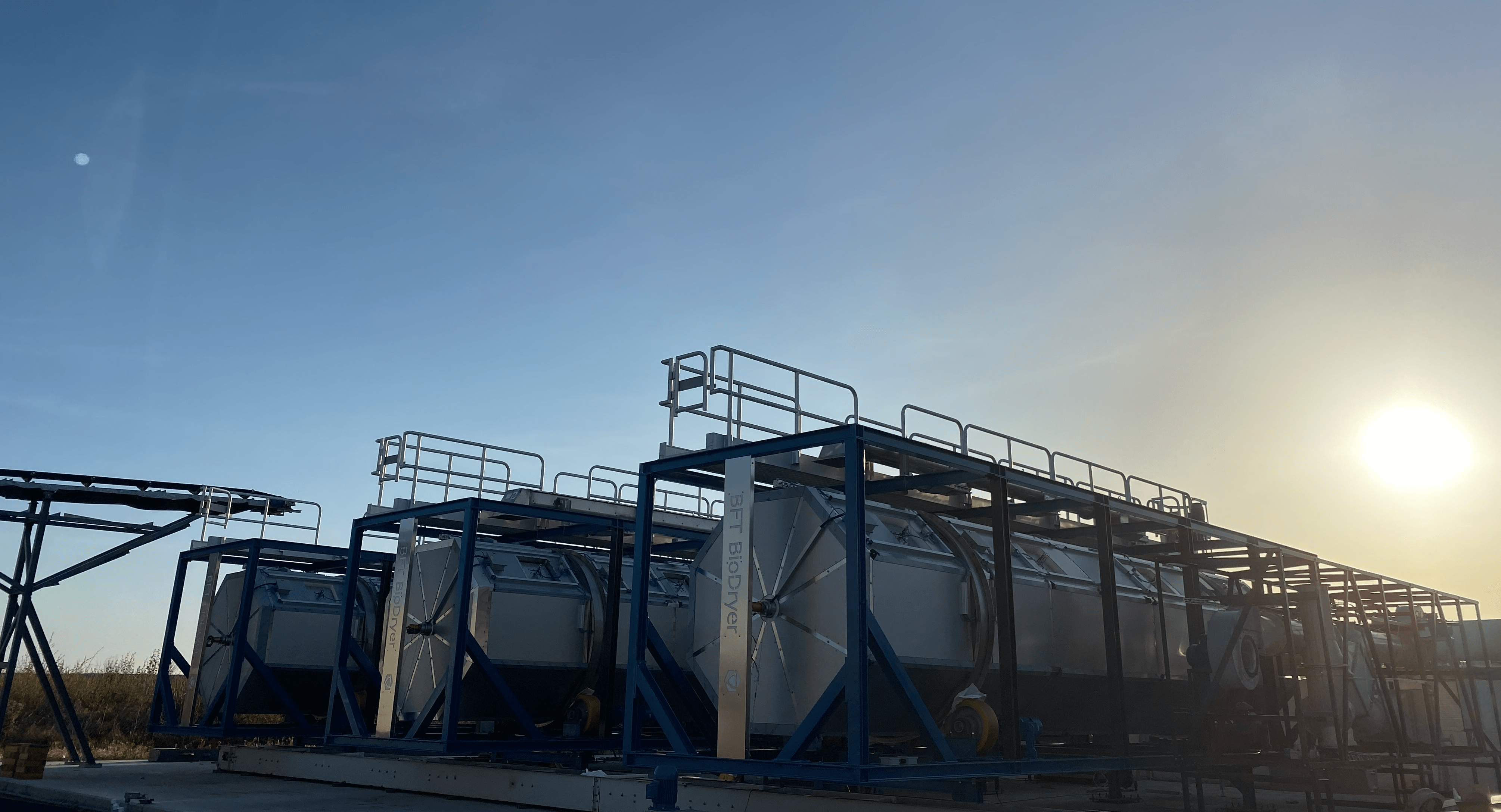

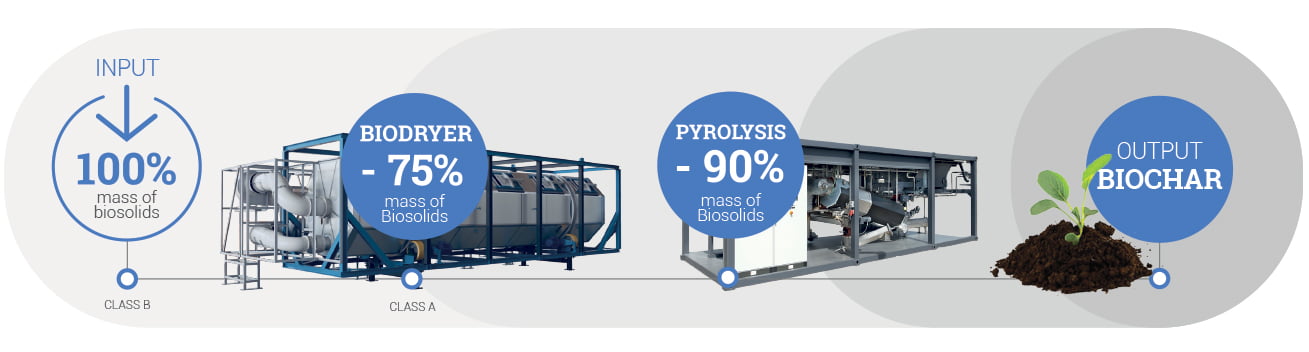

The BioForceTech process is a modular two step system to treat either digested or raw sludge; the process includes BioForceTech’s BioDryer followed by pyrolysis. Overall, the process reduces solids volume by 90%, there are no additives required (only biosolids) and the system can be either energy neutral or energy positive.

By-products include syngas and a valuable carbon rich biochar material. The P-Five pyrolysis reactor has also been shown as an effective method for removing PFAS and PFOA from municipal biosolids.

The Cambi Thermal Hydrolysis Process improves Anaerobic Digestion by using high temperature and pressure to break down complex substrates before they are introduced to the digestion process. Sludges treated through the Cambi process can also be introduced into a Digester at a much higher concentration. The results of incorporating Cambi at a WWTP are: up to 50% higher biogas production, increased digester throughput, improved dewaterability, and a Class A Biosolid.

The JDV Double Membrane Gas Holder is a proven design to store digester gas with low total cost of ownership. Compared to other methods of gas storage, the double membrane gas holder is easier to install, has lower upfront capital costs, and requires lower operating capital. The double membrane design allows for variable gas storage within the inner membrane at constant pressure during gas production and utilization. Air held in the other layer of the gas holder provides pressure and protection which makes the consistency of pressure in the inner layer possible. Operators have full control of optimizing the utilization of gas to feed generators and heating systems, aided by the feedback provided by an ultrasonic sensor at the middle of the sphere which monitors the volume of gas present.

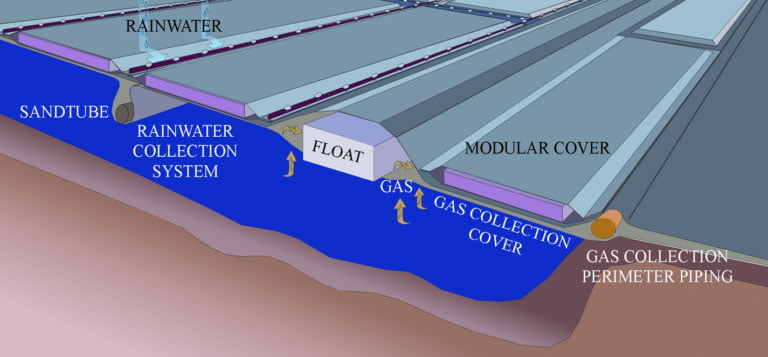

The LemTec™ Gas Cover System is comprised of a custom-engineered, rigid, durable geo membrane cover that isolates liquid in lagoons and tanks from ambient air, allowing no diffusion of odor vapors, and a piping system to draw off gas produced under the cover using negative pressure. A LET gas cover can be paired with a LemTec™ Modular Insulated Cover System for heat retention to maintain optimal digester performance or for additional protection of gas collection from ice, debris, and UV. Access ports can be designed into the system for equipment maintenance and sampling, and the cover itself is easy to remove for tank or lagoon maintenance.