Have You Checked??

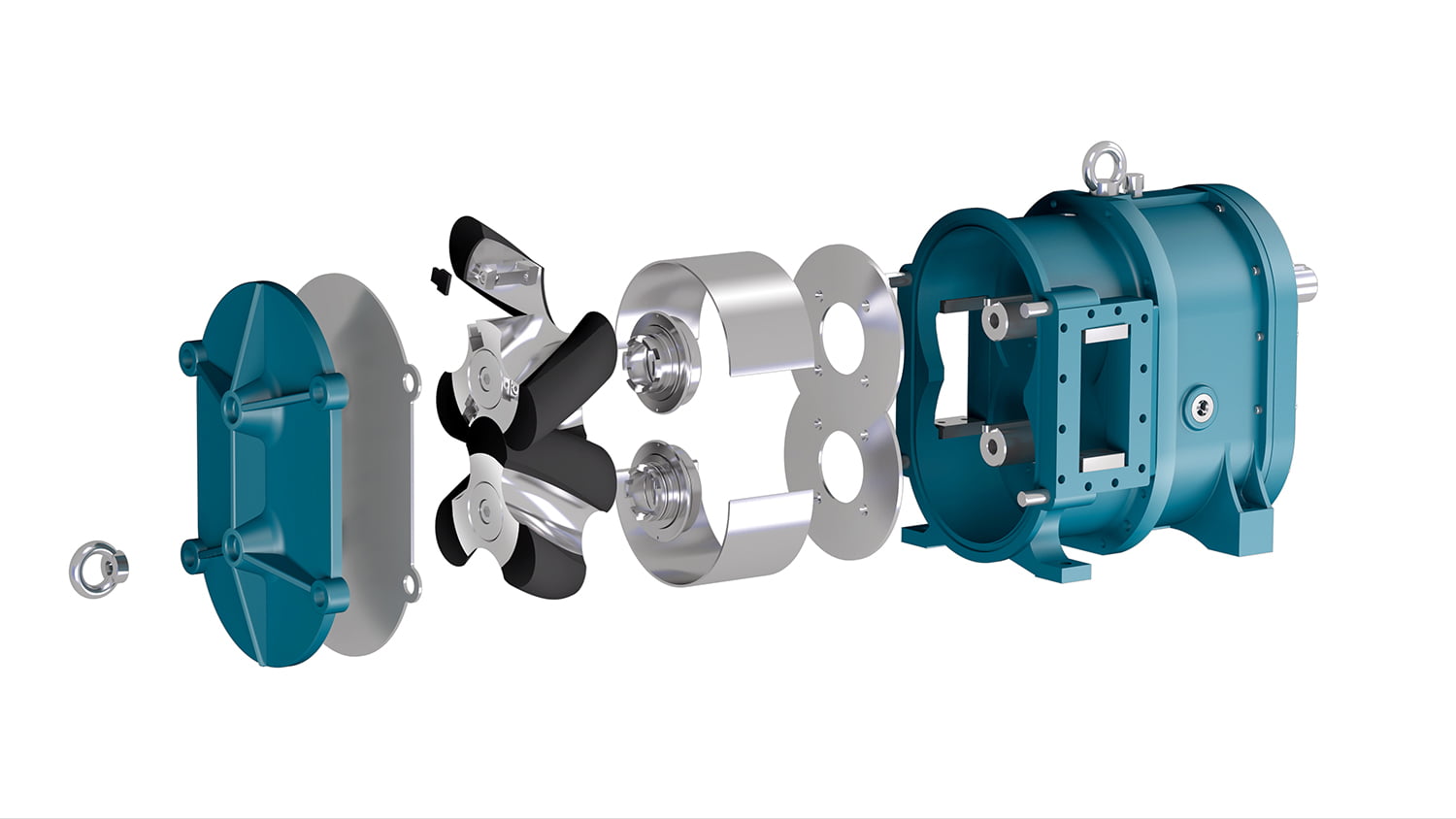

Do you have a Boerger Rotary Lobe pump and have thought to yourself, “What does routine maintenance on this pump look like”? Waste ‘n WaterTech is happy to answer that and share with you some helpful tips to keep your Boerger Rotary Lobe pump running smoothly and efficiently!

Daily Checks:

- Visual checks for leaks

- Making sure that the pump is audibly running smoothly

Weekly Checks:

- Check pump functions, flow rates, and pressures

Monthly Checks:

- Confirm oil level in gear chamber sight glass is at the half-way mark

- Confirm oil level in intermediate chamber is at the correct level (covering the top shaft).

- Confirm intermediate chamber oil is in good condition

*If either oil is low, refill as necessary and confirm no leaks*

*If either oil is low, refill as necessary and confirm no leaks*

Every 3 Months:

- Check the pump, motor, gear reducer, and components for tight fit and possible damage

Every 1 Year:

- Replace pump gear chamber and intermediate chamber oils

Every 2 years (or 10,000 hours of operation, whichever comes first):

- Replaced Nord gear reducer oil

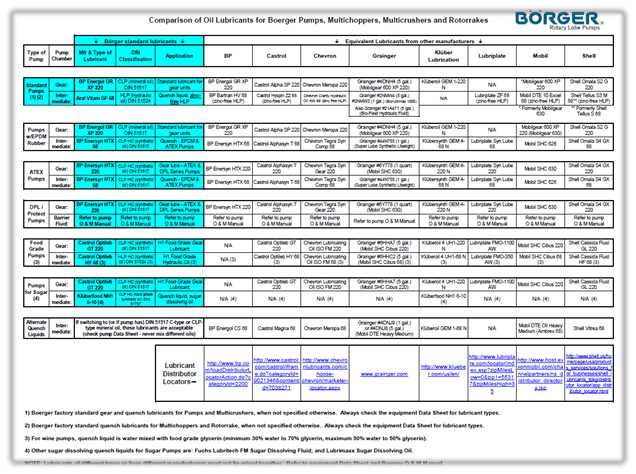

Below is Boerger’s approved list of oils that can be safely used with your Boerger Rotary Lobe Pump. It is imperative that only oils specially listed in the chart below (based on specific pump application) be used. Oils not listed in this chart could adversely affect the longevity and operation of your pump!

If you have any questions regarding pump maintenance, Boerger Rotary Lobe pump operation, or just need some advice, please do not hesitate to contact Waste‘n WaterTech Ltd. We will happily answer any questions that you may have.